Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

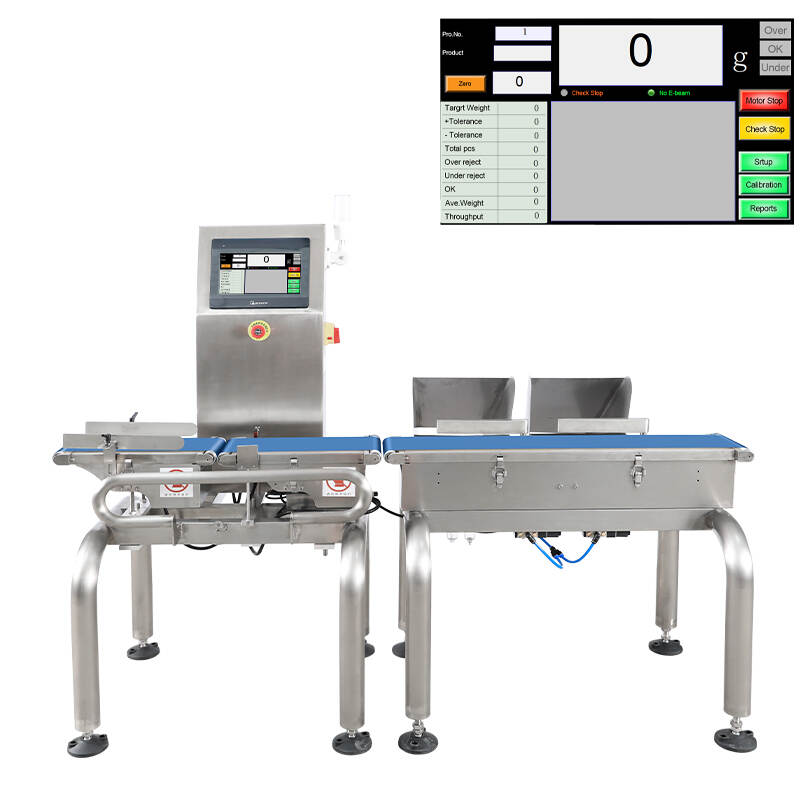

Checkweigher-for heavy objects

-

USD 4,000.00 ~ USD 5,500.00/unit

1/ unit (Min. Order)

Introducing our Checkweigher for heavy objects, designed to ensure accurate weight measurement in industrial settings. This robust system guarantees precision and efficiency in verifying the weight of heavy items during production processes. Equipped with advanced technology, it optimizes workflow and enhances quality control. Trust our checkweigher for reliability and productivity.

The inline dynamic checkweigher -suitable for heavy objects, is a high-speed, high-precision check weigher. It can be seamless integrated with various packaging production lines and conveying systems. A high sensitivity checkweigher for weighing check. It can be seamless integrated with various packaging production lines and conveying systems.

The top quality of the components and materials ensures great machine sturdiness and longevity, just as the easily removable and washable plates allow for quick cleaning and maintenance.

•Superior Performance—Inline check weighing for packaged products; lowers product waste/loss and improves efficiency

•Quick and Accurate—Self-controlled operation; unique signal processing and auto-zeroing technology ensures product weighing accuracy even with seafood or marinated products

•Flexible—Suitable for packaged products of all sizes

•Reliable—Stable design maintains accuracy without frequent calibration

•Detection Integration—Seamlessly pairs with metal detectors for a complete product inspection system

•Advanced Features—Quick product switching, robust data collection and analysis, multi-language operator controls and more

Features

◆High accuracy and automated check weighing and sorting machine

◆Touch screen operation:10-inch color touch screen

◆Fast switching: Up to 10 quick menus, seamless docking products for non-stop switching products

◆Three color signal lights: Easy to understand

◆Signal feedback: Provide production trend feedback signals, adjust the packaging accuracy of the upstream packaging machine

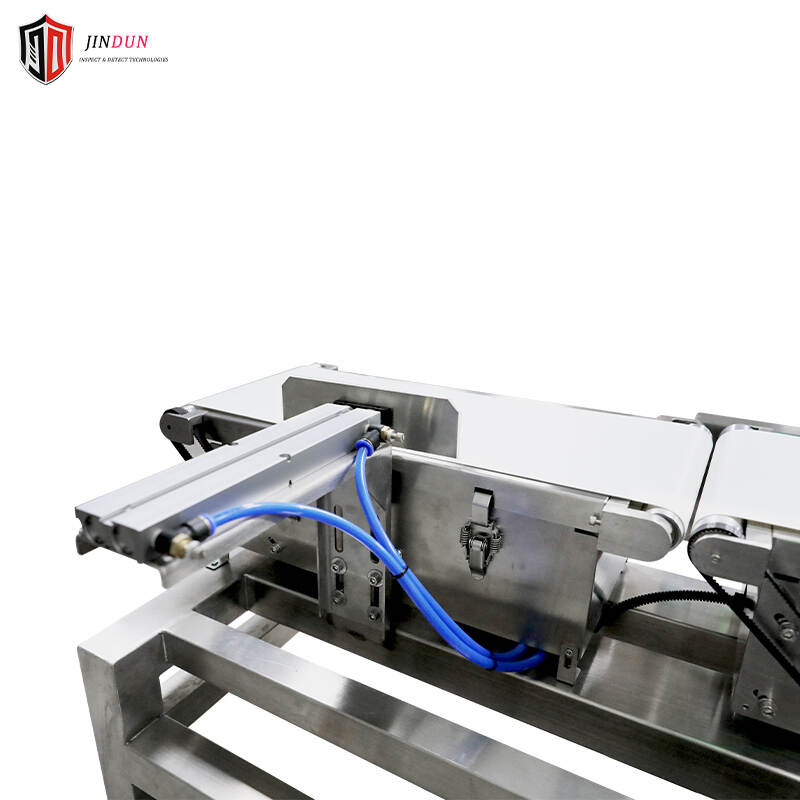

◆Elimination device: The push rod rejector device prevents the product from falling down during the sorting process and spills the material (flexible rejection methods for different products

◆Safe PU food conveyor fast belt

◆Zero trackings: Cleared manually or automatically, and dynamic zero tracking

◆Query printing: Disqualified products can be queried for recording and printing

◆Easy to clean: Buckle design fast belt change system

Specification:

◆Equipment size(mm): 750*580

◆Weighing Size(mm): 270*220

◆Belt surface height(mm): 650-750 (can be customized)

◆Delivery method:Flat belt (belt width: 220 mm)

◆Weighing range: 1.5g~300g

◆Minimum scale: 0.1g

◆Elimination method: Push rod type

◆Material & surface treatment:Stainless steel 304 polishing

◆Operation screen display: English

◆Power supply: 220V±20%

◆Protection level: Comply with IP-65 international standards

Remarks

Checkweighers are the last step before your products are sent to your customer. The checkweigher can be set up in various different ways, with the majority of JINDUN’s checkweigher being bespoke for each and every customer.

The JINDUN checkweigher shown above is a 'general' machine with specifications and options that we feel will cover the majority of customers requirements. These checkweighers are usually kept in stock. Should you require a more bespoke checkweigher, please call our sale dept and we can quote you for your requirements.