Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

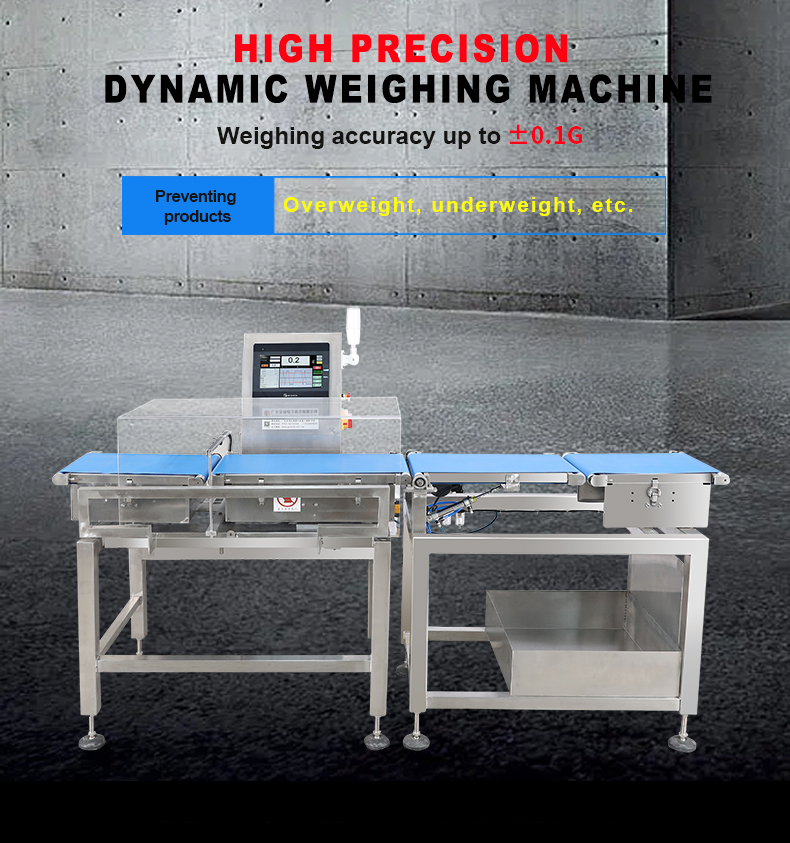

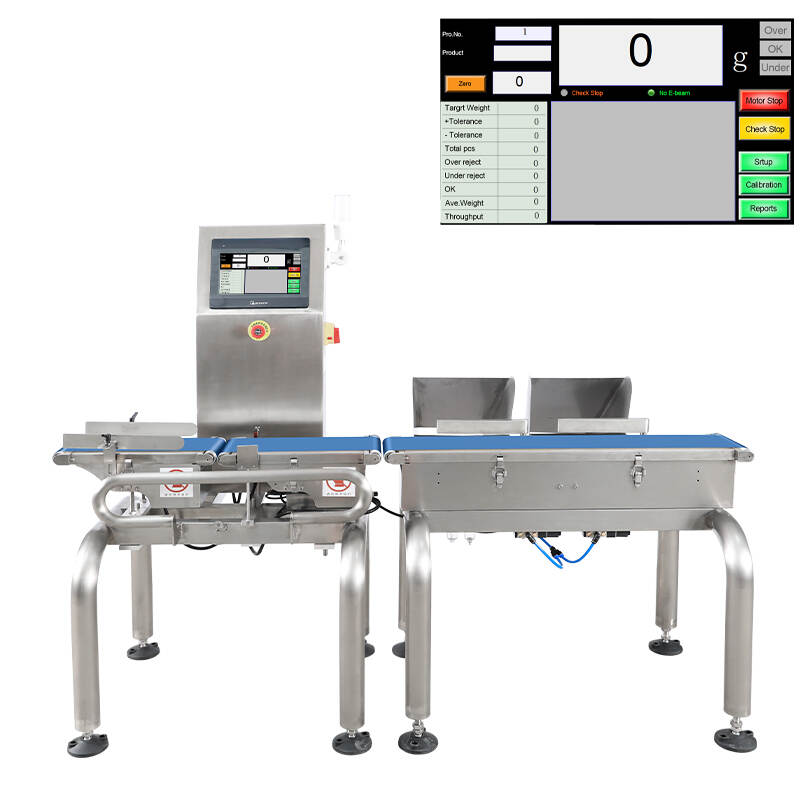

Automatic online accuracy checkweigher manufacture

-

≥1/piece

USD 3,799.00

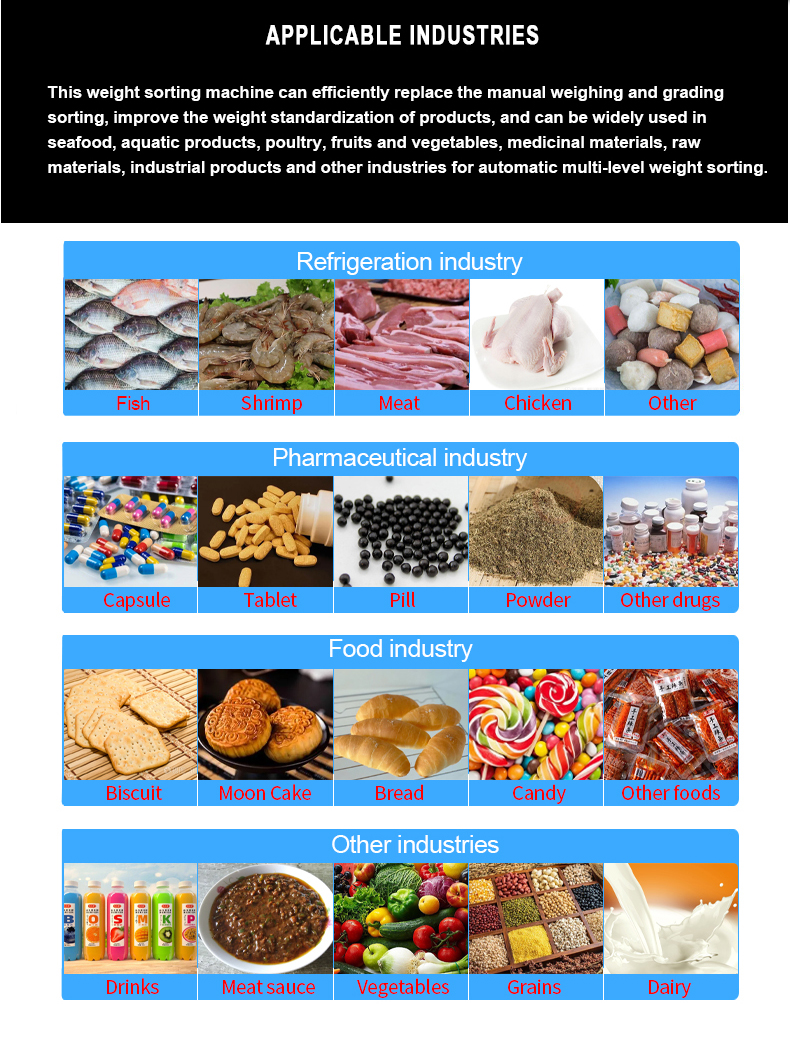

Automatic online accuracy checkweighers are advanced industrial systems designed to ensure the precise weighing of products during production processes. They are crucial in industries where accurate weight measurements are essential for quality control and compliance with regulations.

Description of Product

Automatic online accuracy checkweighers employ sophisticated technology to accurately measure the weight of products as they move along production lines. These systems are integrated seamlessly into the manufacturing process and are typically placed after filling or packaging stations. They work by comparing the weight of each product against preset parameters, rejecting any items that fall outside the acceptable range.

Features of Product

1. High Accuracy: Checkweighers utilize precise weighing mechanisms and advanced sensors to ensure accurate measurements.

2. Speed: They are capable of handling high-speed production lines, maintaining efficiency without compromising accuracy.

3. Versatility: These systems can accommodate a wide range of product sizes, shapes, and weights, making them suitable for diverse manufacturing environments.

4. Automatic Rejection: Checkweighers automatically reject underweight or overweight products, ensuring only items within specified tolerances proceed down the line.

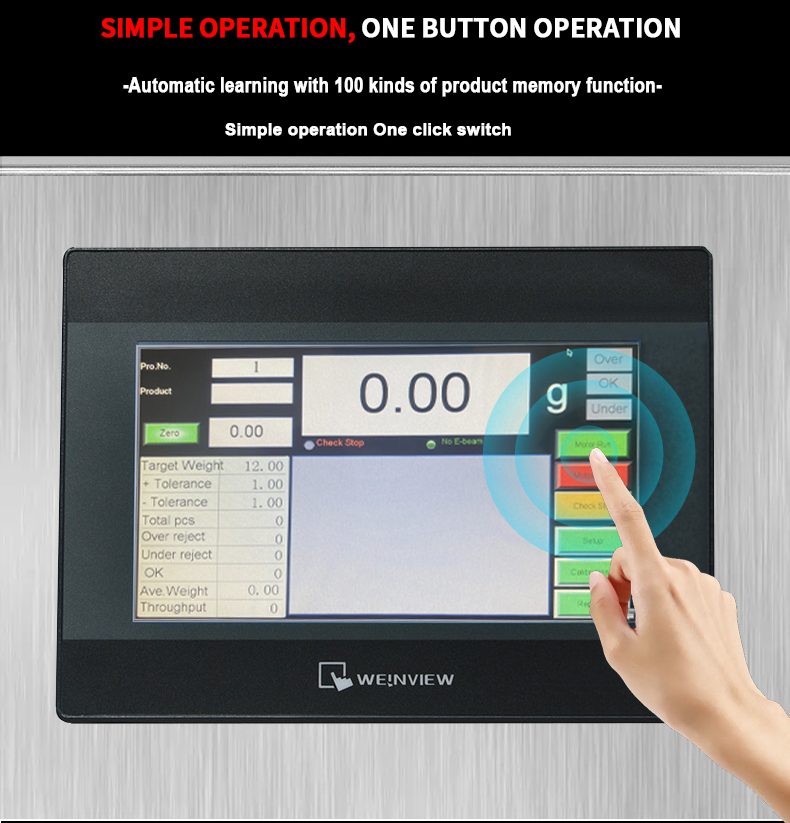

5. Data Logging: Many models feature data logging capabilities, allowing manufacturers to track and analyze production statistics for quality assurance purposes.

6. User-Friendly Interface: Intuitive interfaces make these systems easy to operate and configure, minimizing downtime and streamlining production processes.

Advantages of Product

1. Quality Assurance: By ensuring products meet weight specifications, checkweighers contribute to maintaining consistent product quality.

2. Compliance: They help manufacturers adhere to regulatory requirements and industry standards regarding product weight accuracy.

3. Cost Savings: Preventing the distribution of underweight products reduces the risk of fines, recalls, and reputational damage.

4. Efficiency: Automatic rejection of non-compliant items reduces the need for manual inspection, increasing overall production efficiency.

5. Data Insights: The ability to track and analyze production data provides valuable insights for process optimization and quality improvement initiatives.

Benefits of Product

1. Enhanced Reputation: Consistently delivering accurately weighed products enhances customer satisfaction and builds trust in the brand.

2. Reduced Waste: Minimizing the distribution of underweight products reduces waste and improves resource utilization.

3. Streamlined Operations: Checkweighers contribute to smoother production flows by swiftly identifying and removing non-compliant items.

4. Risk Mitigation: By proactively identifying weight discrepancies, manufacturers can mitigate the risk of costly recalls and regulatory penalties.

5. Competitive Advantage: Investing in advanced checkweighing technology can give companies a competitive edge by demonstrating a commitment to quality and compliance.