Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

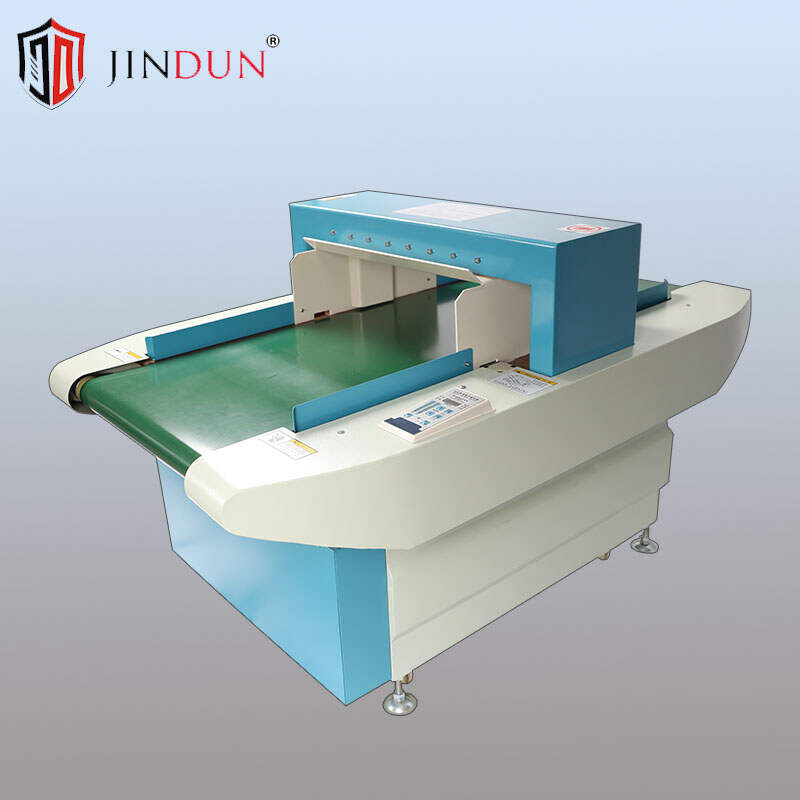

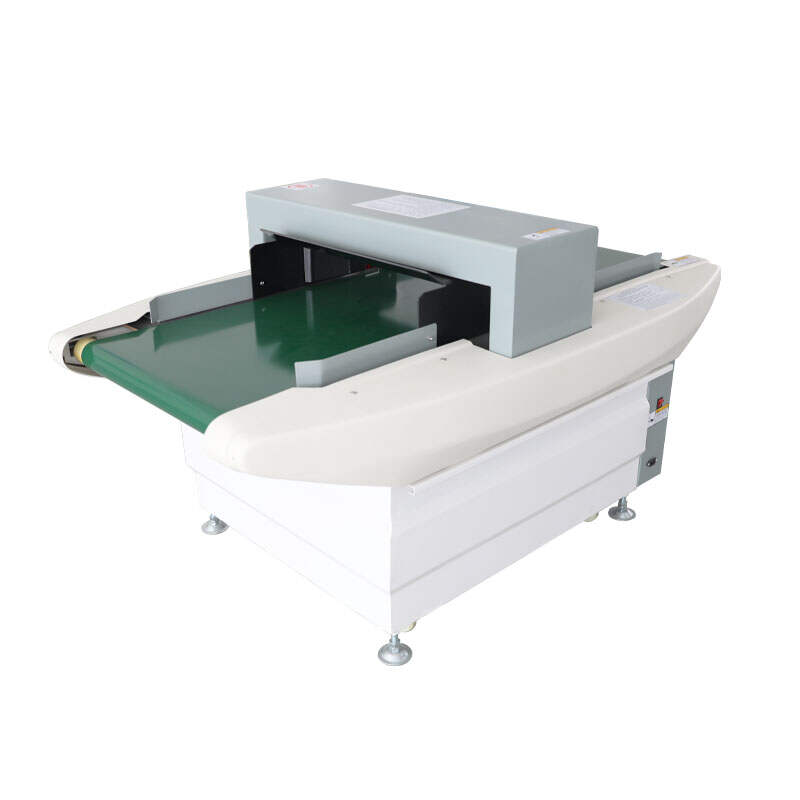

Single Search Head Supplier: Exploring the Evolution and Benefits of Needle Detectors

When it comes to safety and quality control in industries such as food, pharmaceuticals, textiles, and packaging, needle detectors play an indispensable role. As a single search head supplier, understanding the intricacies of these devices and their applications is key to providing the most reliable solutions. This blog will delve into the significance of needle detectors, focusing on single search head models, their functionalities, and how they have revolutionized industries.

What is a Needle Detector?

A needle detector is an essential safety device used to identify and eliminate metallic contamination in products during production and packaging. These detectors are primarily used in industries where even the smallest metallic contamination can lead to hazardous situations or product recalls. The needle detector-single search head variant is designed for precise and accurate detection, typically using a single probe or head to scan products.

Why Opt for a Single Search Head Model?

When considering the purchase of a needle detector, industries often weigh their options carefully. The single search head needle detector offers several advantages. These units are typically more compact, cost-effective, and ideal for businesses with smaller-scale operations. Moreover, the simplicity of a single search head ensures that the machine is easier to operate and maintain compared to multi-head systems.

Compact and Efficient Design

One of the main reasons to choose a single search head supplier is the design of these machines. Single head detectors take up less space and are lighter than their multi-head counterparts. This is especially beneficial for smaller facilities or businesses with limited floor space. Despite their compact size, these detectors deliver high precision, making them perfect for detecting even the smallest metal contaminants.

Cost-Effectiveness

For businesses operating on a budget, single search head models are an ideal solution. They are generally more affordable than multi-head systems while still providing excellent performance. For industries that do not require high-speed scanning of large volumes of products, a single search head system offers a cost-effective means of ensuring product safety.

Versatility in Application

Although single search head needle detectors are designed with simplicity in mind, they are remarkably versatile. They are effective in various industries, from food processing to pharmaceuticals. Their ability to detect even the most minuscule metal particles ensures they can be used for products ranging from food items to delicate pharmaceutical tablets.

How Needle Detectors Work

The operation of a needle detector is straightforward yet sophisticated. Here's a look at how these devices function:

-

Electromagnetic Fields: Needle detectors use electromagnetic fields to detect metal contaminants. When a product passes through the electromagnetic field, any metallic object in the product interferes with the field, triggering an alert.

-

Sensitivity Levels: The sensitivity of the detector can be adjusted based on the type of product being scanned. High-sensitivity detectors can identify even the smallest metal fragments, ensuring maximum safety.

-

Product Conveyor: Most needle detectors are placed along the production or packaging conveyor belts. As products move through the detector, any metal contamination is flagged, and the contaminated product is removed automatically.

-

Single Search Head Configuration: The single search head design utilizes a single probe to detect metal contaminants, which is generally sufficient for smaller-scale operations or certain product types.

Benefits of Choosing a Single Search Head Supplier

There are multiple benefits when opting for a single search head supplier, especially for businesses that are just beginning to implement metal detection systems or those looking for more affordable options.

1. Increased Operational Efficiency

The single search head models are designed to provide quick and accurate results without complicating the process. Their easy integration into production lines means that businesses can streamline their operations and reduce downtime. Once set up, these detectors require minimal maintenance, allowing staff to focus on other aspects of production.

2. Enhanced Product Quality Control

For manufacturers, ensuring that their products meet safety and quality standards is a top priority. A needle detector equipped with a single search head can help identify contamination issues before the product reaches consumers. This process reduces the risk of product recalls and ensures consumer trust.

3. Simplified Maintenance and Support

Compared to multi-head systems, which often require more complex maintenance, a single search head needle detector is much easier to maintain. There are fewer parts to manage, and issues can be resolved more quickly, leading to reduced downtime and lower maintenance costs. Additionally, many single search head suppliers offer ongoing technical support, ensuring that any operational issues can be swiftly addressed.

Industries That Benefit from Needle Detectors

Needle detectors, especially the single search head models, are used across a variety of industries where metal contamination is a serious concern. Here are some key industries that benefit from these devices:

1. Food Industry

In the food industry, the presence of metal contaminants, such as broken machinery parts or metal fragments from packaging, can be detrimental to both consumer safety and brand reputation. A single search head needle detector offers an effective solution to identify metal contamination in food products, ensuring safety and regulatory compliance.

2. Pharmaceutical Industry

The pharmaceutical industry is one of the most sensitive when it comes to contamination risks. Even the smallest metal particle can compromise the integrity of medication. A single search head needle detector can scan pharmaceutical products, such as tablets, capsules, and ointments, to ensure they are free from metal contamination.

3. Textile Industry

Textile products often go through rigorous processing stages, which can lead to metal contamination. A single search head detector can be used in the textile industry to identify metal contaminants in fabrics and finished products, thus preventing costly recalls or safety issues.

4. Packaging Industry

Packaging materials and finished goods are also at risk of metal contamination, particularly when machines or tools break down during production. A single search head model can help identify contaminants in packaged goods, ensuring that only clean, safe products reach consumers.

Choosing the Right Single Search Head Supplier

Selecting the right single search head supplier is crucial for ensuring that you get a high-quality product that meets your specific needs. Here are a few tips to guide you through the process:

1. Understand Your Needs

Before choosing a single search head supplier, assess your production requirements. Consider factors such as the volume of products processed, the sensitivity required, and the space available for installation. A good supplier will help you select the right model based on these factors.

2. Check for Certifications

Make sure that the needle detector meets industry standards and certifications. This is crucial for ensuring the product's reliability and accuracy. Look for certifications such as CE, ISO, and FDA approval, depending on your industry.

3. Evaluate Support and Service

A reliable single search head supplier should offer robust customer support and after-sales service. Make sure that the supplier provides technical assistance, training, and easy access to spare parts and maintenance services.

4. Compare Prices and Warranty Terms

When evaluating suppliers, don't just look at the upfront cost. Compare the warranty terms, customer service offerings, and long-term support provided. A lower initial cost might be tempting, but investing in a higher-quality supplier can save you money in the long run.

Conclusion

In industries where safety and quality are paramount, needle detector-single search head models offer a practical and efficient solution for metal contamination detection. Whether you're looking for a compact, cost-effective option or simply need a reliable safety device for your production line, opting for a single search head supplier can significantly enhance your product quality control process.

By choosing the right supplier, you ensure that your business can maintain high standards of safety while minimizing the risk of metal contamination in your products. The single search head needle detector is an investment in both product integrity and consumer trust, making it a must-have tool in modern industrial operations.